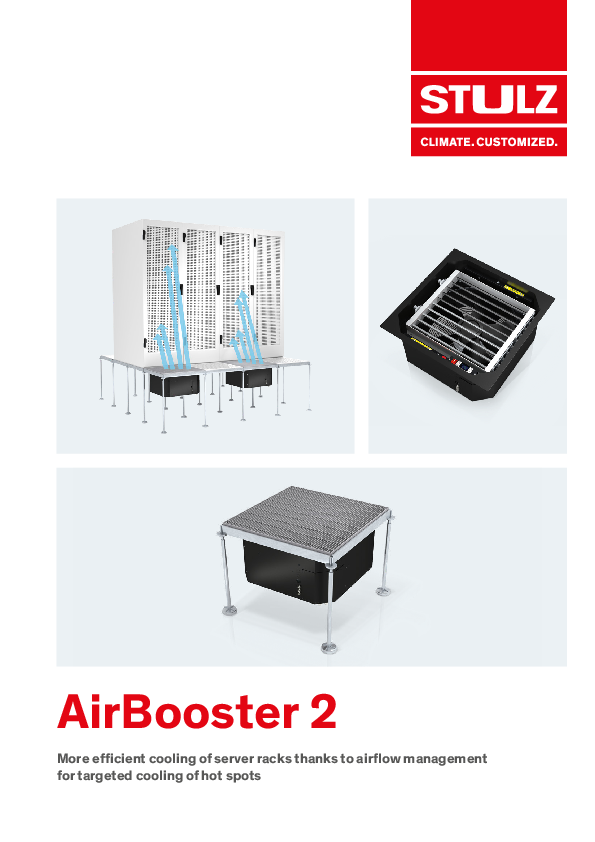

AirBooster 2

For more efficient cooling of server racks

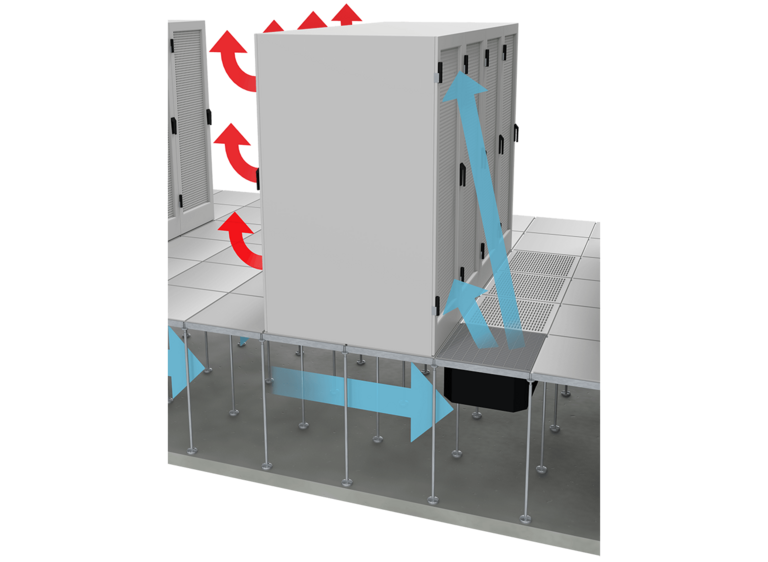

The AirBooster 2 units from STULZ are deployed in the raised floor systems directly in front of the server rack in just a few simple steps. For cooling the server cabinet, they utilize the same air conduction system from the air conditioners to the racks and are controlled exactly in line with cooling needs. Fast, simple and reliable.

Product Overview

Most important benefits

- Optimized inpoint cooling of hot spots in server racks

- Control according to cooling needs for efficient and reliable air supply

- Easy installation, operational in minimal time

Most important features

- Perfect fit for standard raised floor systems with grid size 600mm x 600mm

- Low height allows installation under the raised floor (400mm)

Most important technical data

- Air conduction of up to 4,360 m3/h

- Optimized pinpoint cooling of hot spots in server racks

- Control according to cooling needs for efficient and reliable air supply

- Easy installation, operational in minimal time

- Configurable air conduction fins for targeted air conduction in 2 zones

- EC fan for pinpoint accuracy of air flow supply

- No enclosure required for server cabinet cooling

- Grills available in two designs for individual requirements

- Perfect fit for standard raised floor systems with grid size 600 x 600 mm

- Low height allows installation under the raised floor (400 mm)

- Temperature measurement via 3 sensors

- Optional pressure control

- Low power consumption in rated operation

- Service available worldwide

- UL and CE compliant

- Can be connected to BMS systems

| Air conduction (m3/h) | 2.900 – 4.360 |

| Power consumption (W) | 75 – 474 |

| Dimensions (mm) | 598 × 598 ×260 + grille |

Need more information?

Download our brochure!

All details about AirBooster 2

Airflow management solutions from STULZ

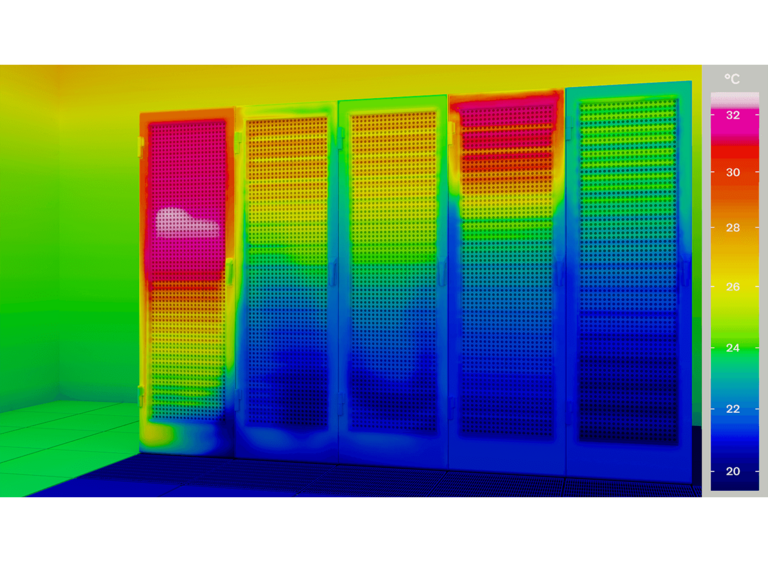

Server racks deployed in a data center feature different heat loads according to the application. In this era of server virtualization and cloud technologies, changing utilization is the requirement that has to be addressed.

This results in an oversupply or undersupply of air to your servers, which can lead to increased operating costs or even superheating followed by server failure.

Airflow solutions from STULZ are installed in the raised floor systems between server racks and air conditioning systems and are thus able to make use of the air conduction of air conditioning systems. Assuming the airflow in the raised floor is sufficient, the units supply the IT exactly with the required amount of cooling. Integrated sensors ensure that cold air requirements are automatically determined and the necessary airflow is provided. Fast, simple and reliable.

For targeted hot spot cooling

Pinpoint cooling of your server racks

The units feature a speed-controlled EC fan, a controller and multiple temperature sensors. These sensors, which are attached to the server at different heights, measure the server inlet temperature. The controller controls the fan speed depending on the measured temperature values and a configurable setpoint.

If the server inlet temperature should rise, the fan speed is increased in order to ensure sufficient cooling of the servers.

Optimum operating conditions thanks to smart control

For units with integrated control

- User-friendly interface and display

- RS485 interface for building management

- RTU Modbus protocol

- Connection terminals for remote control on/off

- Auxiliary contact for general alarm signals

- 3 temperature sensors

- Unit of measurement on temperature display: °C or °F

- Illuminated on/off switch

- LED status light

Raised floor systems: Grilles in two designs

Service and maintenance

As a company with locations across the globe, we offer everything you need in the extremely dynamic world of information technology – plus professional advice in the right place at the right time.

Our trained and experienced sales and service partners are located in over 140 countries. The resulting proximity to our customers allows fast response times. In addition, regular training courses and an active exchange of information ensure high quality and an extensive knowledge of all our products. This way, you can be sure your products are in the best hands and get the right maintenance – all over the world.